Dry sand washing plant

Sand washing machine is widely used in the washing of materials in sand and gravel, mining, building materials, transportation, chemical, water conservancy and hydropower, concrete mixing stations and other industries. Sand washing machines can be divided

Solution

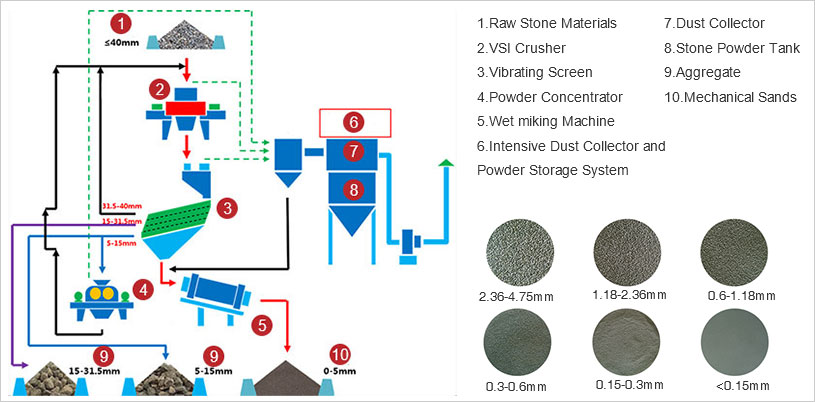

VSI Crusher+Powder Concentrator

Vertical shaft impact crusher with stable and reliable performance(large crusheing ratio: feed size≤80mm);One machine with two functions sand making and aggregate reshaping;Simple process and dynamic powder concentration;Low energy consumption:configuration of single motor makes energy consumption decrease more than 40%;High sand making rate:the final sand products accounts for more than 90%; High quality final products grading: fitness modulus<2.6;

Dry sand making machine production advantages:1. The structure is reasonable, the impeller drive bearing device is isolated from the water and the water-receiving material, which greatly avoids the phenomenon that the bearing is damaged by water immersion, sand and pollutants;

2. There is very little loss of medium fine sand and stone powder.

3. The machine has almost no wearing parts except the screen;

4. Large processing capacity and low power consumption;

5, long service life, easy maintenance;

6. Save water resources;

7, no pollution, high degree of cleanliness.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!