VSI sand making machine

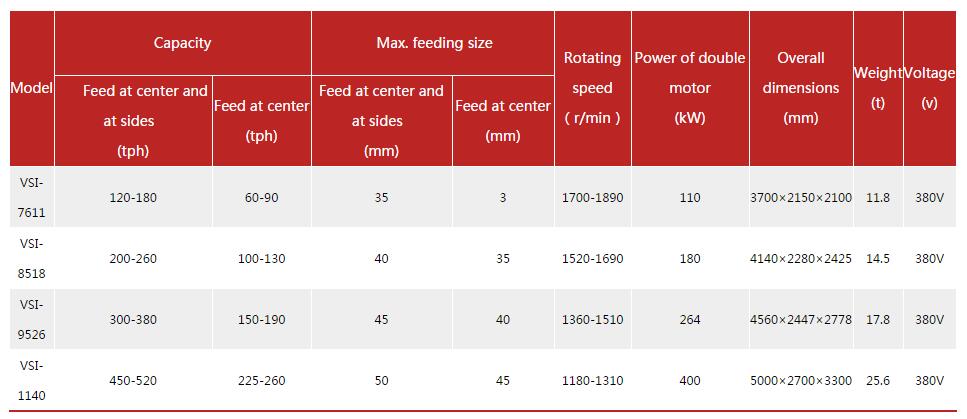

Feed particle size30-50mm.

Processing capacity60-260tph.

Applicable materialRiver pebbles, granite, limestone, iron ore, abrasives, refractory materials, cement clinker, concrete aggregates, etc..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

VSI sand making machine, also known as high-efficiency vertical shaft impact crusher, is an advanced level high-efficiency sand making equipment developed by our company after several technical improvements. Compared with domestic similar products, VSI sand making machine has higher output, good grain shape and low cost of use. This machine is specially designed for highways, high-speed railways, high-rise buildings, municipal, hydropower dam construction, concrete mixing stations, and is a must-have equipment for artificial sand making and stone shaping.

High energy and low consumption

The stone is hit, accelerated, impacted, rebounded and rubbed in the VSI sand making machine, so that the ore is broken along the fragile surface such as joints and until the material specifications are set, so the VSI sand making machine is an advanced high energy. Low-cost sand making equipment.

Sand made finished grain shape is good

The VSI sand making machine has the characteristics of selective crushing, high crushing efficiency and low energy consumption. Moreover, the crushed product has uniform particle size, natural grain shape and firm and stable materials, so it is often used in the construction and engineering fields where sand and gravel materials are strictly required.

Sand making products are better than natural sand

The VSI sand making machine has a shaping function. The broken product is cubic, the needle-like content is extremely low, and the grain type and grading of the sand making can be adjusted and improved, so it is widely used in aggregate shaping and artificial sand making. And high-grade highway aggregate production.

Parameters

Principle

1. According to the feeding mode of the material, the working mode of the centrifugal impact crusher can be divided into complete center feeding and center feeding with waterfall feeding;

2. According to the compressive strength and abrasiveness of the material, the working form of the centrifugal impact crusher can be divided into two types of crushing: “stone stone” and “stone iron”. Therefore, the working form of the vertical shaft sand making machine can be divided into four types: the center feeding is accompanied by the waterfall feeding “stone stone” and “stone hitting iron”, and the complete center feeding “stone stone” and “stone hitting iron”.

3. During the specific operation of the Vertical Shaft Impact Crusher, the material enters the crusher through the feeding hopper, and falls onto the distribution tray through the bulk cone, and the material is divided into two parts. A part of the wheel that enters the high-speed rotation from the middle of the distribution tray is rapidly accelerated in the boring wheel, and then is ejected from the turbulent flow path at a high speed, and another part of the material falling around the distribution tray is impact-broken, and then impacts together with the crushing chamber. On the material lining, after being rebounded, it impacts obliquely upward to the top of the crushing chamber, changing direction and moving downwards, and the material emitted from the turbulent flow channel forms a continuous curtain, so that one piece of material is subjected to multiple impacts in the crushing chamber. Broken by friction and grinding. The crushed material leaves the crushing chamber under gravity and enters the unloading hopper of the lower casing to discharge.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!