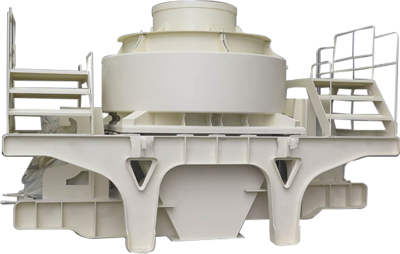

River stone sand making machine

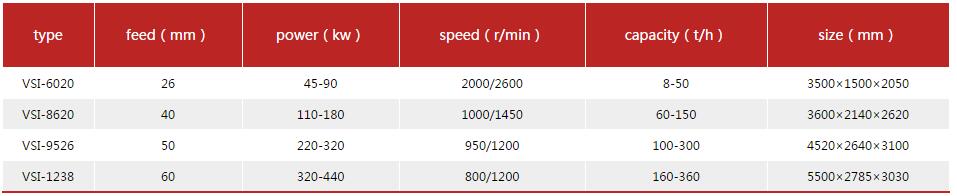

Feed particle size<60mm.

Processing capacity8-360tph.

Applicable materialArtificial sand production of river pebble, limestone, granite, basalt, diabase, andesite, ore tailings, and stone chips.

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

The river pebble sand making machine is suitable for the crushing of soft or medium hard and extremely hard materials, and has the shaping function. The river pebble sand making machine has small particle size, uniform grain size, large production capacity, long hammer life and small supporting power. The third-stage crushing is secondary crushing, the process is simplified, the structure is simple, the maintenance is convenient, and the operation is stable. Especially for high hardness, special hard and abrasion resistant materials, it is more efficient than other types of crushers.

High throughput, high yield

The river pebble sand making machine adopts deep cavity rotor design, which has large throughput, high processing capacity and high output;

Simple structure and easy maintenance

The river pebble sand making machine is small in size, easy to operate, and convenient to install and maintain;

Controllable particle size and excellent grain size

The feeding gate of the river pebble sand making machine can be controlled, and the amount of waterfall is changed to control the particle size of the finished product. The product has excellent grain size and more economic value;

Low cost, high return

The working principle of the equipment is reasonable, and the stone crushing cavity is utilized, the working efficiency is higher, the wearing parts are less worn, the maintenance cost is low, and the return rate is high.

Parameters

Principle

working principle:

The material enters the sand making machine from the feeding hopper, and the material is divided into two parts through the feeder, and a part is inserted into the high-speed rotating impeller from the middle of the distributor, and is rapidly accelerated in the impeller, and the acceleration can reach hundreds of times of gravity acceleration. Then, it is ejected from the three uniform flow channels of the impeller at a speed of 60-70 m/s. Firstly, it is impacted and broken by a part of the material falling from the periphery of the distributor, and then impacted together on the material lining in the vortex cavity. It is rebounded by the material lining, impacts obliquely upward to the top of the vortex chamber, changes its direction of motion, deflects downward, and the material emitted from the impeller runner forms a continuous material curtain. Such a material is subjected to two or even multiple chances of impact, friction and grinding and crushing in the vortex breaking chamber. The broken material is discharged from the lower discharge opening. During the whole crushing process, the materials are crushed and broken by themselves, and are not directly in contact with the metal components, but are impacted and rubbed against the material lining, which reduces the angular pollution and prolongs the mechanical wear time.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!