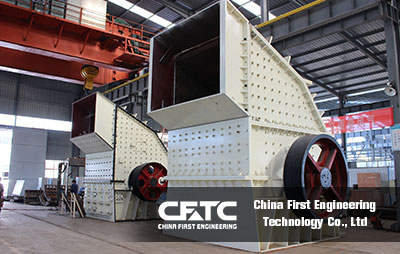

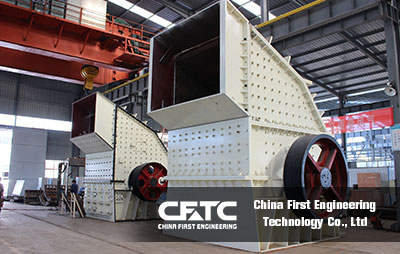

Heavy hammer crusher

Feed particle size600-1200mm.

Processing capacity100-800t/h.

Applicable materialLimestone, coal, salt, white Asia, gypsum, alum, brick, tile, coal gangue, etc..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

The heavy hammer crusher is a new generation of crushed products that have been optimized and manufactured in various mechanical principles of hitting and crushing stones with a crusher hammer (plate hammer). The weight of a single hammerhead is large, the moment of inertia is large, and the rotor speed is high, which fully demonstrates the advantages of large breaking and small crushing and light weight, and has the ability to eat and crush large stone. The machine changes the method of controlling the particle size of the discharge to reduce the wear of the hammer in the crushing chamber, and the life of the hammer is increased by 4-6 times.

Crusher Hammer

Consignment

Impact plate

Performance characteristics:

1. The feeding inlet is large, the crushing chamber is high, and the material hardness is high, the block size is large, and the product has less stone powder.

2, the weight of the hammer crusher is suspended, and the power consumption of the crusher is small.

3, the hammer crusher is a novel hammer with a large impact force.

4. The weight of the hammer crusher is adjustable, and the hammer has a long service life.

5, the grid size is adjustable, the product granularity is controllable, and the particle shape is good.

6, the hammer crusher chassis can be turned over, and the maintenance is more convenient.

7, square handle bolts, impact and wear resistance.

8, the weight crusher is compact and the machine is rigid.

9, the hammer crusher body structure, easy to handle and install.

10, impact, counterattack, impact (stone stone) broken function, high production efficiency, mechanical wear and tear, comprehensive benefits.

Parameters

| Mode | Rotor diameter(mm) | Feed port size(mm) | Feed particle size(mm) | Production capacity | Motor Powerkw) | Dimensions(mm) |

| PCZ1308 | 1310×790 | 850×800 | ≤600 | 100-160 | 132 | 2818×2100×2390 |

| PCZ1510 | 1500×900 | 1000×90 | ≤700 | 160-210 | 132×2 | 3260×2414×2750 |

| PCZ1512 | 1500×1160 | 1200×900 | ≤750 | 250-320 | 160×2 | 3260×2624×2750 |

| PCZ1615 | 1650×1452 | 1500×1200 | ≤1000 | 360-420 | 200×2 | 3456×2915×3185 |

| PCZ1620 | 1660×1900 | 2000×1200 | ≤1200 | 500-800 | 315×2 | 3500×3100×3200 |

Principle

The device can adjust the purlin gap according to the user's requirements and change the granularity of the discharge to meet the different needs of different users. The fast-rotating hammer body and the material collision surface break the material, which has the characteristics of simple structure, large crushing ratio and high production efficiency, and can be used as a dry and wet crushing device. The main working part of the machine is a rotor with a hammer (also known as a hammer). The rotor consists of a main shaft, a disc, a pin and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feed port, and is crushed by the impact, impact, shearing and grinding action of the high-speed moving hammer. In the lower part of the rotor, a sieve plate is provided, and the size of the pulverized material smaller than the mesh size is discharged through the sieve plate, and the coarse-grained grade larger than the mesh size is retained on the sieve plate and continues to be struck and ground by the hammer, and finally passed through the sieve plate. Exhausted from the machine.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!