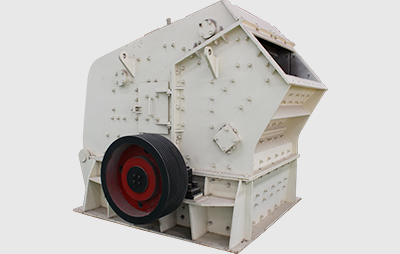

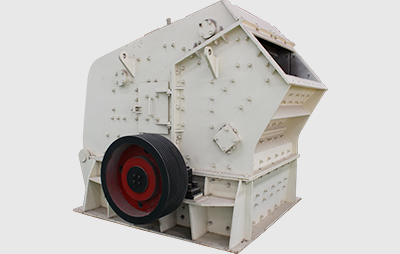

Impact Crusher

Feed particle size35-710(kW).

Processing capacity5-800tph.

Applicable materialVarious mineral ores and rockswhich anti-pressure do not exceed 320Mpa. .

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

Impact crusher is mainly used to crush many kinds of large, medium, small hard size materials with compression resistance no more than 350Mpa,in the fields of highway, reservoir, railway, airport and other fields that need rock with cubic shape. It features in high capacity, high performance, high reduction ratio, cubic shape and low flakiness. The single rotor impact crusher has the characteristics of simple structure, big reduction ratio, low energy consumption,high output,light weight , cubic physique end product. it can supply the uses of industry sectors such as dressing, chemistry, cement, building, fire-proof material, ceramics, glass to use in hitting garrulous and each kind of medium degree of hardness using of in broken bits material, for example: Limestone, chamotte, slag, coke, coal and so on. Compare to hammer crusher,impact crusher has bigger reduction ratio and Can fully use the high speed impact energy of entire rotor.

Liner

Rotor

Consignment

CFTC Impact Crusher has these advantages:

1.Uniformly broken multi-cavity, improving production capacity and saving energy;

2.High chromium new type wear-resistant blow bar, unique toothed impact plate;

3.Shape optimizing function makes the final product cubic;

4.New Design of low speed and multiple crushing cavities sets the rotary speed down by 20-25% and obtain high production capacity under lower energy consumption.

Parameters

| Model | Specification (mm) |

Feed opening (mm) |

Max. feeding size (mm) |

Capacity (tph) |

Power (kW) |

Weight (t) |

| PF-1007 | Φ1000×700 | 400X730 | 250 | 20-70 | 37-55 | 9 |

| PF-1010 | Φ1000X1050 | 400X1080 | 300 | 50-90 | 55-75 | 15 |

| PF-1210 | Φ1250X105 | 400X1080 | 300 | 70-130 | 110 | 17 |

| PF-1214 | Φ1250X1400 | 400X1430 | 300 | 100-180 | 132 | 22 |

| PF-1315 | Φ1320X1500 | 860X1520 | 350 | 130-250 | 200 | 26 |

| PF-1520 | Φ1500X2000 | 960X2020 | 700 | 300-500 | 400-440 | 45 |

| PF-1820 | Φ1800X2000 | 1600X2020 | 700 | 500-700 | 630-710 | 65 |

Principle

The impact crusher is a crushing machine that uses impact energy to break up materials. When the machine is working, the rotor rotates at a high speed under the driving of the motor. When the material enters the action area of the hammer, it collides with the hammer on the rotor, and then is thrown to the counter-attack device to break again, and then rebounds from the counter-attack. Returning to the hammer action zone, the process is repeated. The process is repeated from large to small, and the first, second and third counter-attack chambers are repeatedly crushed until the material is crushed to the required particle size. The stone is discharged from the discharge port directly from the upper part of the machine. Falling into a high-speed rotating turntable; under the action of high-speed centrifugal force, another part of the flying stone that is shunted around the turntable in the form of an umbrella produces high-speed collision and high-density crushing. After the stones hit each other, they will be in the turntable and the casing. The vortex motion is formed between them to cause multiple blows and smashes.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!