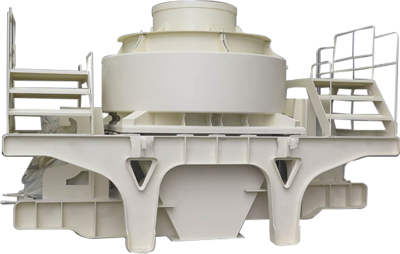

Stone powder sand washing machine

Feed particle size2200-3500mm.

Processing capacity15-200t/h.

Applicable materialWashed vibrating screens are mainly used for deliming and screening operations of sand and gravel in construction sites, sand and gravel plants, prefabricated plants and hydroelectric fields. They can also be used for ore sorting operations..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

The stone powder sand washing machine is a kind of water-washing sand-making auxiliary equipment used in the sand making machine. Its main job is to wash away the stone powder and impurities mixed in the sand during the sand making process, and further improve the purity of the sand. The stone powder sand washing machine adopts advanced technology and combines the actual situation of the domestic sand and gravel industry to develop a high-efficiency sand washing equipment.

Parameters

Stone powder sand washing machine performance advantage

Large throughput

The washing operation of the stone powder sand washing machine can prevent the blockage of the mine bin, the chute, the funnel and the crushing and screening equipment, and improve the processing capacity of the crushing and screening equipment.

Concentrate recovery

Some ore, by washing, can enrich the useful mineral components to obtain qualified concentrates, such as some sedimentary stone materials.

Improve material taste

Limestone for smelting can remove slag by washing, improve the finished product taste and meet the smelting requirements.

Washing height

Its novel sealing structure, adjustable overflow weir plate and reliable transmission ensure the cleaning and dewatering effect, and the clarity is higher.

Principle

working principle

When the stone powder sand washing machine is working, the power unit drives the impeller to slowly rotate through the V-belt, the speed reducer and the gear, and the sand enters the washing tank through the feeding trough to complete the cleaning. The clean sand is taken away by the blades, and finally the sand is poured from the rotating impeller into the discharge chute to complete the cleaning of the sand.

In the process of cleaning materials, it can be divided into difficult to wash, medium washable and easy to wash according to the difficulty of washing the ore in the ore. The difficulty of cleaning is mainly related to the nature, content and existence state of the clay in the ore. Washing can be carried out in a scrubber or in a screening and sorting facility.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!