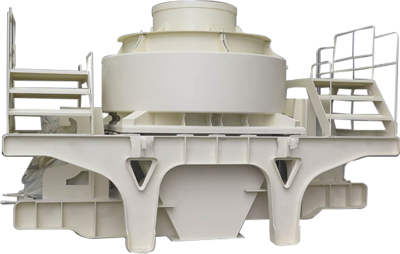

Symons Cone Crusher

Feed particle size22-400(kW).

Processing capacity10-2000tph.

Applicable materialbarite, marble, calcite, kaoline, coal, gypsum, concrete, building wastes etc..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

Symons cone crusher has features of large crushing capacity, high crushing efficiency, low operation cost, convenient adjustment, economical to use, etc. Reasonable materials of spare parts and structure design improves its service life. Moreover, the final products is of uniform and cubic granularity, thus reducing the production load for re-crushing.

Symons cone crusher has longer arm of force than other crushers can provide powerful crushing force. Longer arm of force will produce greater impact torque. Long arm of force which embodied in the main shaft has the characteristics of reducing eccentric bearing load and temperature, and extend bearing’s working life.

Longest stroke of crushing cone will increase the capacity. Longer eccentricity and appropriate cone angle will help crusher get bigger discharging volume.

Symons cone crusher with powerful crushing force and material’s gravity will get higher efficient and lower

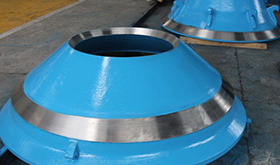

Concave & mantlet

Spring

Consignment

1. High-performance. Combining optimal designing of chamber type with applying reasonable speed and stroke;

2. Higher capacity and less wearing costs.

3. Wide range of application suitability.

4. Easy to maintain, reduce the downtime and maintenance costs.

5. Stable running performance and easy operation.

Parameters

| Specification | Model | Cavity type | Max. diameter of moving cone (mm) |

Discharge opening (mm) |

Max. feeding size(mm) |

Power (kW) | Weight (t) | Overall dimensions(mm) |

| 2'FT | PSGB-0607 | (F) | 600 | 6-38 | 60 | 22 | 4500 | 2195×1158×1651 |

| 2'FT | PSGB-0609 | (M) | 600 | 10-38 | 80 | 22 | 4500 | 2195×1158×1651 |

| 2'FT | PSGB-0611 | (C) | 600 | 13-38 | 90 | 22 | 4500 | 2195×1158×1651 |

| 2'FT | PSGD-0603 | (F) | 600 | 3.0-13 | 30 | 22 | 4500 | 2195×1158×1651 |

| 2'FT | PSGD-0605 | (C) | 600 | 5.0-16 | 40 | 22 | 4500 | 2195×1158×1651 |

| 3'FT | PSGB-0910 | (F) | 900 | 9.0-22 | 85 | 75 | 9980 | 2656×1636×2241 |

| 3'FT | PSGB-0917 | (C) | 900 | 13-38 | 150 | 75 | 9980 | 2656×1636×2241 |

| 3'FT | PSGB-0918 | (EC) | 900 | 25-38 | 150 | 75 | 9980 | 2656×1636×2241 |

| 3'FT | PSGD-0904 | (F) | 900 | 3.0-13 | 35 | 75 | 10530 | 2656×1636×2241 |

| 3'FT | PSGD-0906 | (M) | 900 | 3.0-16 | 65 | 75 | 10530 | 2656×1636×2241 |

| 3'FT | PSGD-0907 | (C) | 900 | 6.0-19 | 85 | 75 | 10530 | 2656×1636×2241 |

| 4.25'FT | PSGB-1313 | (F) | 1295 | 13-31 | 115 | 160 | 22460 | 2983×1866×3156 |

| 4.25'FT | PSGB-1321 | (M) | 1295 | 16-38 | 178 | 160 | 22460 | 2983×1866×3156 |

| 4.25'FT | PSGB-1324 | (C) | 1295 | 19-51 | 205 | 160 | 22460 | 2983×1866×3156 |

| 4.25'FT | PSGB-1325 | (EC) | 1295 | 25-51 | 220 | 160 | 22460 | 2983×1866×3156 |

| 4.25'FT | PSGD-1306 | (F) | 1295 | 3.0-16 | 54 | 160 | 22590 | 2983×1866×3156 |

| 4.25'FT | PSGD-1308 | (M) | 1295 | 6.0-19 | 76 | 160 | 22590 | 2983×1866×3156 |

| 4.25'FT | PSGD-1310 | (C) | 1295 | 8.0-25 | 89 | 160 | 22590 | 2983×1866×3156 |

| 4.25'FT | PSGD-1313 | (EC) | 1295 | 16-25 | 113 | 160 | 22590 | 2983×1866×3156 |

| 5.5'FT | PSGB-1620 | (F) | 1676 | 16-38 | 178 | 220 | 43270 | 3941×2954×3771 |

| 5.5'FT | PSGB-1624 | (M) | 1676 | 22-51 | 205 | 220 | 43270 | 3941×2954×3771 |

| 5.5'FT | PSGB-1626 | (C) | 1676 | 25-64 | 228 | 220 | 43270 | 3941×2954×3771 |

| 5.5'FT | PSGB-1636 | (EC) | 1676 | 38-64 | 313 | 220 | 43270 | 3941×2954×3771 |

| 5.5'FT | PSGD-1607 | (F) | 1676 | 5.0-13 | 60 | 220 | 43870 | 3941×2954×3771 |

| 5.5'FT | PSGD-1608 | (M) | 1676 | 6.0-19 | 76 | 220 | 43870 | 3941×2954×3771 |

| 5.5'FT | PSGD-1613 | (C) | 1676 | 10.0-25 | 113 | 220 | 43870 | 3941×2954×3771 |

| 5.5'FT | PSGD-1614 | (EC) | 1676 | 13-25 | 113 | 220 | 43870 | 3941×2954×3771 |

| 7'FT | PSGB-2127 | (F) | 2134 | 19-38 | 236 | 400 | 86730 | 4613×3302×4638 |

| 7'FT | PSGB-2133 | (M) | 2134 | 25-51 | 284 | 400 | 86730 | 4613×3302×4638 |

| 7'FT | PSGB-2136 | (C) | 2134 | 31-64 | 314 | 400 | 86730 | 4613×3302×4638 |

| 7'FT | PSGB-2146 | (EC) | 2134 | 38-64 | 391 | 400 | 86730 | 4613×3302×4638 |

| 7'FT | PSGD-2110 | (F) | 2134 | 5.0-16 | 89 | 400 | 89500 | 4613×3302×4638 |

| 7'FT | PSGD-2113 | (M) | 2134 | 10.0-19 | 113 | 400 | 89500 | 4613×3302×4638 |

| 7'FT | PSGD-2117 | (C) | 2134 | 13-25 | 151 | 400 | 89500 | 4613×3302×4638 |

| 7'FT | PSGD-2120 | (EC) | 2134 | 16-25 | 172 | 400 | 89500 | 4613×3302×4638 |

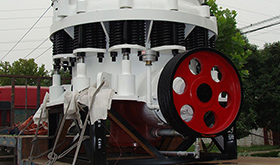

Principle

The crushing cavity of symons cone crusher consists of the moving cone and the fixed cone. The moving cone is installed on the upper of the main shaft under pressure, while one end of the main shaft is inserted into the conical hole of the eccentric bush. The conical hole of the eccentric shaft bush is internally equipped with the bronze bush or nylon bush. When the transmission gear drives the eccentric shaft bush, the main shaft inserted into the eccentric shaft bush drives the moving cone to keep cycloidal rotation so that the space between the mantle and concave will regularly reduce and increase to squeeze materials and discharge the final crushed materials.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!