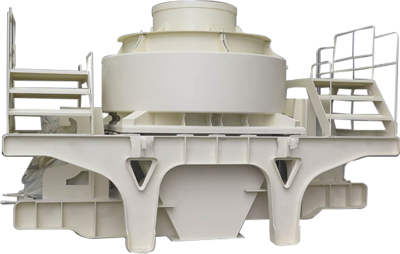

Mobile crushing station

Feed particle size300-750mm.

Processing capacity70-500t/h.

Applicable materialMany sectors such as mining, smelting, building materials, roads, railways, water conservancy and chemical industries, especially for the operation of mobile materials such as highways, railways, and hydropower projects..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

The mobile crushing station can be used for mining, building materials, roads, railways and other industries to complete the crushing and screening operations at one time, and produce the material size and output required by the users. It is mainly used for metallurgical, chemical, building materials, hydropower and other materials processing that often require relocation operations, especially for the operation of mobile materials such as highways, railways, water conservancy and hydropower projects. Users can use a variety of configurations depending on the type, size and finished material requirements of the raw materials.

Mobile Jaw Crusher Station

Mobile Impact Crusher

Mobile Cone Crusher

CFTC Mobile crushing station has many advantages:

1, strong mobility

The tire mobile crushing station has a short length. Different crushing equipments are installed on separate movable chassis. The wheelbase is short and the turning radius is small, which can be flexibly driven on ordinary roads and working areas.

2. Integrated complete unit

The integrated unit equipment installation form eliminates the complicated site infrastructure installation work of the split components and reduces the material and working hours. The reasonable and compact space layout of the unit improves the flexibility of the station.

3, reduce material transportation costs

The mobile crushing station can process materials on site without having to move the materials away from the site for further processing, which greatly reduces the transportation cost of materials.

4, the effect of the operation is directly effective

The integrated series of mobile crushing stations can be used independently, or it can provide more flexible process configuration for the material types and product requirements of the customers in the process, and meet various requirements such as mobile crushing and moving screening, so that the organization can be generated. Logistics transfer is more direct and effective, and the cost is maximized. 5, flexible combination, adaptability

The mobile crushing plant can be composed of “first crushing and then crushing” according to different crushing process requirements, or it can be composed of “first screening and crushing” process; it can be combined into coarse crushing and fine crushing two-stage crushing screening system according to actual needs, or combined. It is a three-stage crushing and screening system with coarse crushing, medium crushing and fine crushing. It can also run independently and has great flexibility.

Parameters

【Jaw crusher series】:

| model | LTE-69 | LTE-710 | LTE-912 | LTJ-811 |

| Feeder model | ZSW-380×96 | ZSW-420×110 | ZSW-490×130 | ZSW-490×130 |

| PE broken model | PE-600×900 | PE-750×1060 | PE-900×1200 | JC-840×1100 |

| Main belt conveyor model | B800×8.5M | B1000×9M | B1200×9.5M | B1200×9.5M |

| Side belt conveyor model (optional) | B450×3M | B500×3.5M | B650×4M | B650×4M |

| Maximum feed (mm) | 480 | 630 | 750 | 720 |

| Outlet adjustment range(mm) | 65-160 | 80-140 | 95-165 | 100-225 |

| Production capacity(t/h) | 90-180 | 110-320 | 220-450 | 200-500 |

| Motor Power(kw) | 180 | 220 | 250 | 270 |

| Shipping size(L×W×H)(mm) | 11900×2550×3650 | 13100×2550×4450 | 14600×2950×4500 | 14600×2550×4500 |

| biggest size(L×W×H)(mm) | 12100×2900×4060 | 13300×2950×4810 | 14600×3300×5300 | 14600×3300×5300 |

| Iron remover (optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-12 | RCYD(C)-12 |

| Tire configuration | And installed double axis C | And installed three-axis C | And installed four-axis C | And installed four-axis C |

【Impact crusher series】:

| model | LTF-1210 | LTF-1214 | LTFW-1214 | LTFW-1315 | LTFW-1315 |

| Feeder model | ZSW-380×96 | ZSW-380×96 | ZSW-380×96 | ZSW-420×110 | ZSW-420×110 |

| Counterattack broken model | PF-1210 | PF-1214 | PEW-1214S | PF-1315 | PFW-1315S |

| Main belt conveyor model | B800×8.5M | B800×8.5M | B800×8.5M | B1000×9.M | B1000×9.M |

| Side belt conveyor model (optional) | B450×3.2M | B450×3.2M | B450×3.2M | B500×3.5M | B500×3.5M |

| Maximum feed(mm) | 300 | 300 | 500 | 350 | 600 |

| Production capacity(t/h) | 70-130 | 90-180 | 130-200 | 120-250 | 180-320 |

| Motor Power(kw) | 220 | 270 | 270 | 350 | 330 |

| Shipping size(L×W×H)(mm) | 11900×2550×3900 | 11900×2600×3900 | 11900×2550×3650 | 13100×2900×4450 | 13100×2800×4150 |

| biggest size(L×W×H)(mm) | 12100×2900×4310 | 12100×2950×4310 | 12100×2950×4310 | 13300×2950×4810 | 13300×2950×4810 |

| Iron remover (optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 |

| Tire configuration | And installed double axis C | And installed double axis C | And installed double axis C | And installed double axis C | And installed double axis C |

Principle

The main crushing equipment of the mobile crushing station can be equipped with a jaw crusher, a counter crusher and a cone crusher. The material is evenly conveyed into the crusher through the feeder. After being crushed by the crusher, the circular vibrating screen constitutes a closed circuit system. The material is recycled and broken, and the material that meets the particle size requirements is output by the conveyor to achieve the production purpose. The mobile crushing station can also remove the circular vibrating screen according to the actual production needs, and directly crush the material, and then carry out specific operations with other crushing equipment, which is convenient and flexible.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!