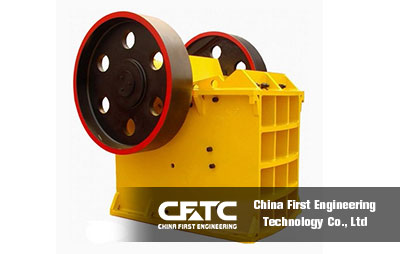

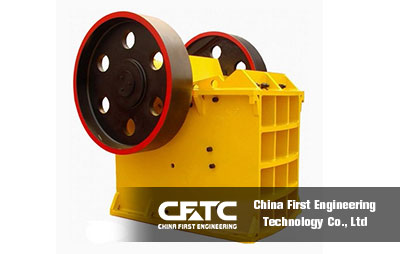

Jaw Crusher

Feed particle size15-220(kW).

Processing capacity5-800tph.

Applicable material:Limestone, shale, calcium carbide, carbide slag, bluestone, basalt, river pebble, copper, ore, etc..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

The jaw crusher is abbreviated as PE. This series of products has the characteristics of large crushing ratio, uniform product size, simple structure, reliable work, simple maintenance and economical operation. It can be widely used in mining, smelting, building materials, roads, railways and water conservancy. And in many sectors such as the chemical industry, crushing various materials with a compressive strength not exceeding 320 MPa.

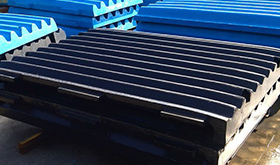

Moving Jaw Plate

Fixed Jaw Plate

Consignment

1.High crushing ratio, uniform granularity of final product.

2.Optimized discharge port adjustment device makes large adjusting range, and the whole machine is more reliable and convenient and flexible.

3.Safe and reliable lubrication system makes the parts replacement easily and decreases the maintenance workload.

4.Simple structure, convenient maintenance, low operation cost, low noisy and dust.

5. Crushing cavity is deep and there is no dead area, which improves the feeding capacity and output.

6. High reduction ratio and uniform final product size.

7. The adjustment device of discharge-hole is reliable and convenient.

8. Reliable and safe lubrication system, convenient replacement of parts and small workload of maintenance.

9. Simple structure, operational reliability and low operation cost.

Parameters

| Model | Feeding opening(mm) | Max. feeding size (mm) | Adjustable discharge opening (mm) | Capacity (tph) | Power (kW) | Weight (t) |

| PE-250x400 | 250x400 | 210 | 20-80 | 5--20 | 15 | 2.8 |

| PE-400x600 | 400x600 | 340 | 40-100 | 16-60 | 30 | 7 |

| PE-500x750 | 500x750 | 425 | 50-100 | 40-110 | 55 | 12 |

| PE-600x900 | 600x900 | 500 | 65-160 | 90-180 | 55 | 17 |

| PE-750x1060 | 750x1060 | 630 | 80-140 | 110-320 | 110 | 29 |

| PE-900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 110-132 | 58 |

| PE-1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 |

| PEX-150x750 | 150x750 | 120 | 18-48 | 8--25 | 15 | 3.5 |

| PEX-250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 |

| PEX-250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 37-45 | 8.52 |

| PEX-300x1300 | 300x1300 | 250 | 20-90 | 10-65 | 75 | 13.5 |

Principle

Taking the traditional jaw crusher as an example, as a kind of curved crushing crushing equipment, when the E-breaking machine works, the electric motor drives the belt and the pulley, and moves the movable jaw up and down through the eccentric shaft, and when the moving jaw rises, the bracket is The angle between the moving jaws becomes larger, so that the moving jaw is approached to the fixed jaw, and at the same time the material is crushed or crushed to achieve the purpose of breaking; when the moving down, the angle between the bracket and the moving jaw becomes smaller. Under the action of the pull rod and the spring, the movable jaw leaves the fixed jaw, and the broken material is discharged from the lower mouth of the crushing chamber. As the motor rotates continuously, the crushing maneuvering cycle motion crushes and excretes the material to achieve mass production.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!