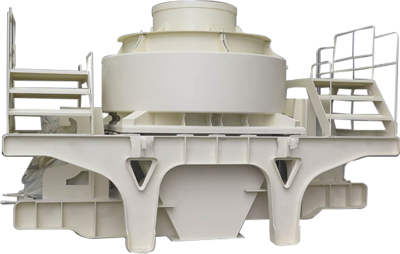

Mobile screening plant

Feed particle size200-400mm.

Processing capacity60-1300tph.

Applicable materialBluestone, limestone, pebbles, phosphate rock, kaolinite, dolomite, diabase, basalt, quartz sand, etc..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

The design of the Mobile screening plant is upgraded and improved on the basis of the traditional vibrating screen. The traditional vibrating screen is fixedly placed in one place, while the mobile vibrating screen changes the traditional fixing method and has the characteristics of strong mobility, eliminating the need for The construction of infrastructure such as piling in the early stage of fixed vibrating screen.

The Mobile screening plant is applied to the post-crushing section, and as a direct connection device for coarse and fine crushing, the granular materials of different sizes can be sieved. It is suitable for the screening of various ores such as granite, river pebbles, bluestone, basalt, limestone, etc. The screening effect is remarkable. According to customer requirements, single-layer, double-layer and three-layer screening equipment can be designed.

1. Mobility is convenient and fast, and can be customized according to the actual needs of customers, and the design style is diversified.

2, the use of durable materials, quality, long service life, excellent running performance.

3. The structure design is simplified, the investment cost is low, and the return period is short.

4. The screening capacity is large, the screening efficiency is high, the finished product has no impurities and the quality is good.

5, simple maintenance, hydraulic automatic upgrade system, simple operation, no manual operation, automatic production throughout the process.

6. Silent production during operation, no dust pollution, low energy consumption, significant energy saving and environmental protection effect.

Parameters

| type | Number of layers | inclination (°) |

power (kw) |

frequency (r/min) |

Maxt-input (mm) |

Capacity(t/h) | size(mm) |

| 2CFTC1545 | 2 | 18 | 15 | 780-900 | 200 | 60-500 | 5380×2295×1410 |

| 3CFTC1545 | 3 | 18 | 15 | 780-900 | 200 | 65-500 | 5575×2295×1990 |

| 4CFTC1545 | 4 | 18-20 | 18.5 | 780-900 | 200 | 65-500 | 5765×2295×1990 |

| 2CFTC1855 | 2 | 18 | 18.5 | 780-900 | 200 | 75-600 | 5680×2565×1450 |

| 3CFTC1855 | 3 | 18 | 22 | 780-900 | 200 | 75-600 | 5900×2460×2110 |

| 4CFTC1855 | 4 | 18-23 | 22 | 780-900 | 200 | 75-600 | 6030×2565×2500 |

| 2CFTC2165 | 2 | 18 | 30 | 780-900 | 200 | 85-700 | 7160×2990×1690 |

| 3CFTC2165 | 3 | 18 | 30 | 780-900 | 200 | 85-700 | 7380×2990×2365 |

| 4CFTC2165 | 4 | 18-23 | 37 | 780-900 | 200 | 85-700 | 7430×2990×2550 |

| 2CFTC2465 | 2 | 18 | 37 | 780-900 | 200 | 100-800 | 7160×3290×1690 |

| 3CFTC2465 | 3 | 18 | 37 | 780-900 | 200 | 100-800 | 7380×3290×2365 |

| 4CFTC2465 | 4 | 18-23 | 37 | 780-900 | 200 | 100-800 | 7430×3290×2500 |

| 2CFTC2765 | 2 | 18 | 37 | 780-900 | 200 | 120-900 | 7180×3570×1805 |

| 3CFTC2765 | 3 | 18 | 45 | 780-900 | 200 | 120-900 | 7390×3570×2445 |

| 4CFTC2765 | 4 | 18-23 | 45 | 780-900 | 200 | 120-900 | 7480×3570×2715 |

| 2CFTC3065 | 2 | 18 | 37 | 780-900 | 200 | 200-1200 | 7180×3870×1805 |

| 3CFTC3065 | 3 | 18 | 45 | 780-900 | 200 | 200-1200 | 7390×3870×2445 |

| 4CFTC3065 | 4 | 18-23 | 45 | 780-900 | 200 | 200-1200 | 7480×3870×2715 |

| 2CFTC3075 | 2 | 18 | 22×2 | 780-900 | 400 | 200-1300 | 8700×4055×1980 |

| 3CFTC3075 | 3 | 18 | 37×2 | 780-900 | 400 | 200-1300 | 8940×4120×2720 |

Principle

Mobile screening plant structure and composition:

The mobile vibrating screen structure consists of a moving fra:me, a tire, a vibrating screen, an electric control system, a motor, etc., and two, three, and four layers of screens can be designed according to customer requirements, according to different specifications of the discharge size requirements. The installation of different layers of screens makes the device simple and easy to use.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!