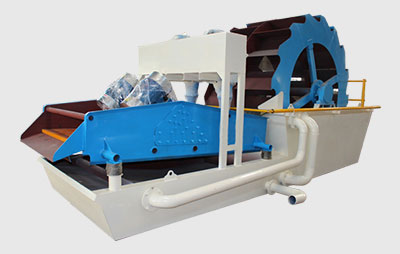

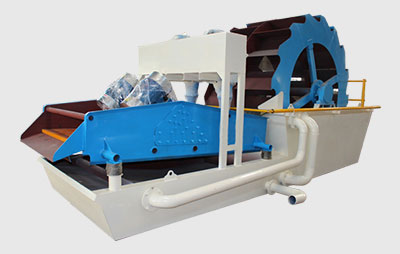

Sand washing & recycling machine

Feed particle size28-83(kW).

Processing capacity20-150tph.

Applicable material Limestone, calcite, barite, dolomite, potassium feldspar, bentonite, medical stone, rock phosphate, manganese ore, iron ore, quartz, active carbon, carbon black, ceramic, coal, ect..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

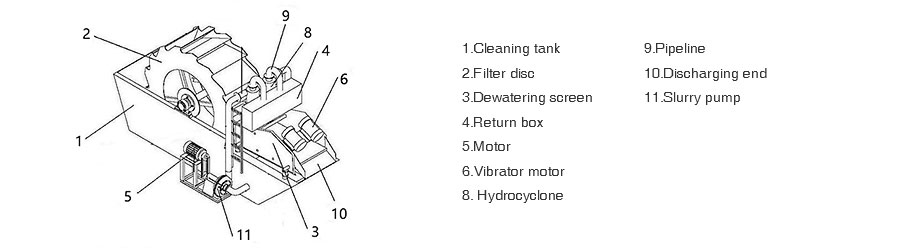

Sand washing & recycling machine is designed based on sand washer and sand recycling system and adopted foreign advanced technology. This machine main parts include: XSD wheel sand washer, high frequency dewatering screen, high pressure cyclone, cleaning tank, return box, high pressure wearable slurry pump, motors, etc. The machine has simple structure and multiple function, and is widely used for crushed sand, river sand, lake sand or sea sand washing, screening, recycling and dewatering.

Return box

Dewatering screen

Consignment

2. The bearing device of impeller drive is separated from water and 1 materials with water, to avoid the damage of the bearing.

3. New sealing structure and reliable transmission device.

4. Reasonable structure.

5. High capacity, low power consumption.

6. Easy structure, stable operation.

Parameters

| Model | Diameter of bucket wheel(mm) | Capacity(tph) | Power(kW) | Weight(t) |

| XS2600I | 2600 | 20-50 | 5.5 | 2.4 |

| XS2600II | 2600 | 30-70 | 5.5 | 2.9 |

| XS2800 | 2800 | 50-100 | 7.5 | 4 |

| XS3200 | 3200 | 80-120 | 11 | 6.6 |

| XS3600 | 3600 | 120-180 | 15 | 8.8 |

Principle

1. Sand washing & recycling machine has reasonable design and convenient use. It mainly has the following structural components: motor, vacuum high pressure pump, sediment separator, TS dewatering screen, cleaning tank and return tank.

2. Working process: the pumping sand water mixture is sent to the mud sand high pressure separator, and the tailing sand concentrated by centrifugation is supplied to the dewatering screen through the grit nozzle. After dewatering through the dewatering screen, the tail sand is effectively separated from the water, and a small amount of tail sand, mud, etc. After returning to the cleaning tank through the return tank, when the liquid level of the cleaning tank is too high, it is discharged through the discharge port. The weight of the recovered material in the dewatering sieve is 70%-85%. Adjusting the fineness modulus can be achieved by changing the pump speed, changing the mortar concentration, adjusting the amount of overflow water, and replacing the mortar nozzle. This completes the functions of cleaning, dehydration and classification.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!