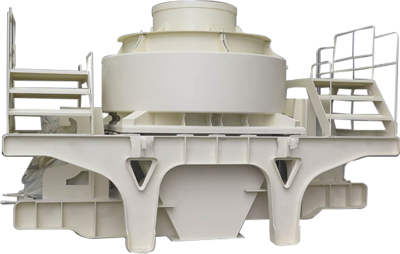

Hydraulic Cone Crusher

Feed particle size130-450(kW).

Processing capacity5-800tph.

Applicable materialVarious mineral ores and rockswhich anti-pressure do not exceed 320Mpa. .

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

High efficient hydraulic cone crushers adopts computer optimization designto speed up main shaft speed. It is often used for crushing stone. The unique crushing chamber replacesystem can quickly replace components in crushing chamber to meetdifferent size requirement. The friction disc design and rotation ofeccentric shaft bushing around fix cone plus more reasonable "labyrinthseal" system are unique features of , which have moread vantages like easier operation, larger application scope, morereliable, more smooth functioning comparing with spring and traditionalcone crusher. It is the most ideal equipment for large stone crushing factory and mining industry. This small stone hydraulic cone crushers widely used for crushing stone.

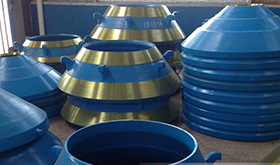

Concave liner

Hydraulic cylinder

Consignment

1.Higher rotating speed and stroke make production capacity which improved 35%-60%.

2.Better finished product shape.

3.Hydraulic protection and hydraulic cavity clearing, high automatization and less stopping production and repairing time.

4.Thin oil lubrication makes the life time increased. 5.Hydraulic motor makes the adjustment of discharging opening size and replacement of wear parts more convient.

Parameters

| Model | Cavity type (mm) | Standard type | Short head type | Power (kW) | Capacity (tph) | ||

| Feed opening (mm) | Min.discharge opening (mm) | Feed opening (mm) | Min.discharge opening (mm) | ||||

| HPM200 | (EC) | / | / | / | / | 132-200 | 90-250 |

| (C) | 185 | 19 | 76 | 10 | |||

| (M) | 125 | 17 | 54 | 6 | |||

| (F) | 95 | 13 | 23 | 6 | |||

| (EF) | 0 | 0 | 10 | 5 | |||

| HPM300 | (EC) | 230 | 25 | 180-250 | 115-440 | ||

| (C) | 210 | 20 | 75 | 75 | |||

| (M) | 150 | 15 | 2--19 | 50 | |||

| (F) | 105 | 10 | 20 | 20 | |||

| (EF) | / | / | 20 | 20 | |||

| HPM400 | (EC) | 295 | 30 | / | / | 280-355 | 140-630 |

| (C) | 250 | 25 | 90 | 10 | |||

| (M) | 195 | 20 | 50 | 8 | |||

| (F) | 110 | 14 | 40 | 6 | |||

| (EF) | 30 | 6 | |||||

| HPM500 | (EC) | 330 | 30 | / | / | 355-450 | 175-790 |

| (C) | 285 | 25 | 90 | 13 | |||

| (M) | 200 | 20 | 55 | 10 | |||

| (F) | 133 | 16 | 40 | 8 | |||

| (EF) | / | / | 35 | 6 | |||

| Model

|

Open circuit closed discharge(mm)

|

||||||||||

| t/h | 10(mm) | 13(mm) | 16(mm) | 19(mm) | 22(mm) | 25(mm) | 32(mm) | 38(mm) | 45(mm) | 51(mm) | |

| HPM200 | t/h | 90-120 | 120-150 | 140-180 | 150-190 | 160-200 | 170-220 | 190-235 | 210-250 | 210-250 | 210-250 |

| HPM300 | t/h | 115-140 | 150-185 | 180-220 | 200-240 | 220-260 | 230-280 | 250-320 | 300-380 | 350-440 | |

| HPM400 | t/h | 140-175 | 185-230 | 225-280 | 255-320 | 275-345 | 295-370 | 320-430 | 360-490 | 410-560 | 465-630 |

| HPM500 | t/h | 175-220 | 230-290 | 280-350 | 320-400 | 345-430 | 365-455 | 405-535 | 445-605 | 510-700 | 580-790 |

Principle

Hydraulic cone crusher consists of frame, support sleeve, adjustment ring, movable cone, eccentric sleeve, transmission device and safety device. The motor drives the transmission shaft rotating, and the transmission shaft drives the eccentric sleeve rotating round the main shaft which is fixed. The eccentric sleeve makes the movable cone in rotary and pendulum movement to achieve the result of continuous crushing

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!