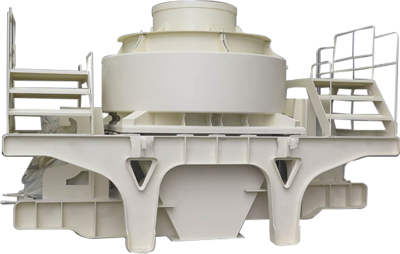

Spiral sand washer

Feed particle size11-18.5*2 (kW).

Processing capacity100-350tph.

Applicable materialsand and gravel plant, mining, construction materials, communication.

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

Introduction to the products of spiral sand washer:

CFTC sand washer is widely used in sand and gravel yards, mines, building materials, transportation, chemical industry, water conservancy, hydropower, concrete mixing station and other industries to wash materials. It is also an indispensable sand production line and gravel production line

1. The loss of fine sand and stone powder is very little.

2. The sand washer has almost no vulnerable parts except screen.

3. Long service life, no maintenance for a long time.

Characteristic of sand washer:

1. Sand washer has simple structure and stable performance. The impeller rotating bearing device is separated from water and water-receiving materials, which greatly avoids bearing damage caused by immersion, sand and pollutants.

2. Zhengke Sand Washing Machine adopts advanced technology and combines the actual situation of domestic and foreign sand and stone industry to develop high-efficiency sand washing equipment. The sand washing machine has high cleanliness, reasonable structure, large output, less sand loss in sand washing process, especially its transmission part is separated from water and sand. Therefore, the failure rate of the sand washing machine is much lower than that of the common sand washing machine at present. For the equipment of sand production line, the sand washing machine is an indispensable equipment.

3. Long service life, rarely need maintenance, so it can greatly reduce costs.

Parameters

The structure of sand washing machine is composed of:

1. The structure of the sand washer is simple. The impeller drive bearing device is isolated from water and water-receiving materials, which greatly avoids bearing damage caused by immersion, sand and pollutants.

2. Compared with the traditional spiral sand washer, the sand washer has obvious advantages when it is used for sand washing in sand and gravel yard as follows:

A. The loss of medium and fine sand and stone powder is very little. The gradation and fineness modulus of the washed building sand meet the national standards of Sand for Construction and Pebble and Crushed Stone for Construction.

B. The sand washer has almost no vulnerable parts except screen.

C, long service life, no maintenance for a long time.

Principle

The working principle of sand washing machine:

When the sand washer works, the motor drives the impeller to rotate slowly through the triangle belt, reducer and gear deceleration. The sand and stone feed trough enters the washing trough, rolls under the impeller's impeller's impeller's impeller's impeller's impeller's impeller's impeller, grinds each other, removes the impurities covering the surface of the sand and destroys the vapor layer covering the sand grains to facilitate dewatering. At the same time, the water is added to form a strong Take it away and drain it from the overflow flume to complete the cleaning function. Clean sand and gravel are taken away by the blades. Finally, the sand and gravel are poured into the discharge trough from the rotating impeller to complete the cleaning of the sand and gravel.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

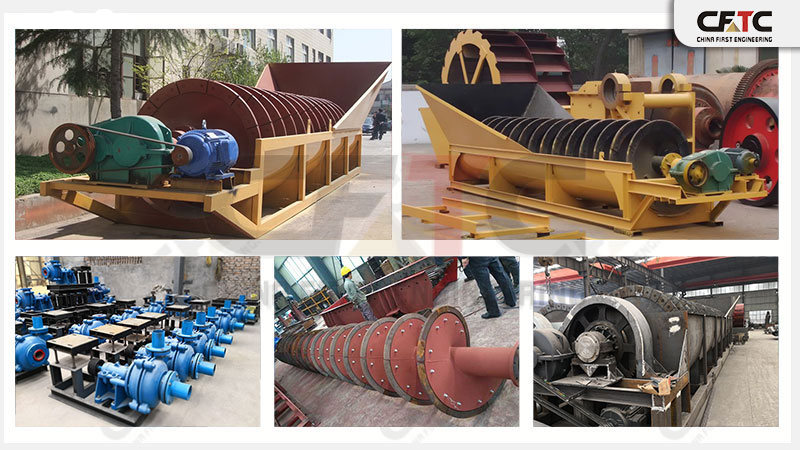

Hot Product

Pursuit of excellence, innovation is not limited!