Tin ore crusher plant

Tin ore is denser than symbiotic minerals. Therefore, re-election is generally used for tin ore beneficiation technology. However, due to the existence of various iron oxide minerals in minerals, such as magnetite, hematite, etc., these minerals cannot be

Part I

Tin ore is denser than symbiotic minerals, so re-election is generally used for tin ore beneficiation. However, due to the existence of various iron oxide minerals in minerals, such as magnetite, hematite, etc., these minerals cannot be separated from tin ore well by re-election or flotation, so they are also used. To magnetic separation or flotation work.

The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore apply gravity separation. However, all kinds of Iron oxides exist in those ore, like magnetite, hematite, etc., which cannot be well separated by using gravity or flotation separation. Herein, magnetic separation and flotation separation will be used. This production line is of compact and reasonable structure, lower investment, convenient maintenance and wide application range, which is used in a variety of stone crushing and ore crushing. It is the best choice for projects in primary and medium scale.

Part II

The density of tin ore is bigger than paragenetic mineral , so we use gravity concentration to processing tin ore . Because there are many oxide iron ore inside , for example : magnetite , hematite , if use gravity concentration or flotation , that could not separate them from tin , so magnetic will be added .

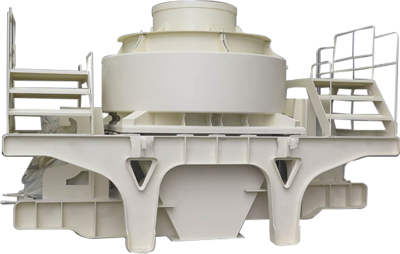

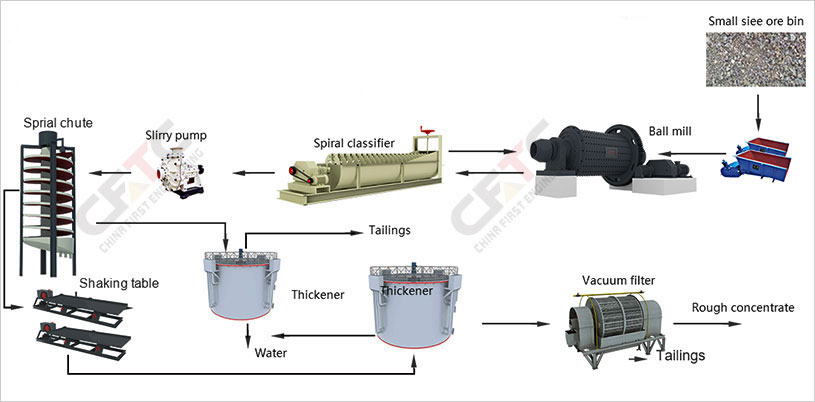

Tin ore beneficiation production line process: First, the original ore is fed into the jaw crusher by a loader, the ore is crushed to about 10mm, and sent to the sand making machine for medium crushing and fine crushing to break the joint between the tin ore and the gangue. After the fine crushing, it is classified into a spiral classifier through a tin mine, and is classified into two sizes of coarse and fine particles for sorting. Fine-grained tin ore has a high degree of dissociation and low yield. It is advisable to use a shaker for recycling. The test of our factory proves that the recovery rate of the shaker here is higher than that of other re-election equipment, and the shaker sorts out the concentrate and tailings. After that, the coarse-grain tin mine enters the jig for sorting. Here, the main purpose of the jig re-election is to recover all the sand-sand minerals. The highest re-election recovery rate is required instead of improving the concentrate grade. Jig The produced coarse concentrate enters the sand making machine for fine crushing, breaking the tin minerals existing in the continuous structure of the coarse concentrate, and the tailings are directly discarded. The role of the sand making machine in the entire tin ore dressing production line is very important, and it is the core equipment of the entire tin ore dressing production line.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!