Manganese crusher plant

The manganese ore processing and production process mainly includes three processes of crushing, grinding and beneficiation

Part I

The manganese ore processing and production process mainly includes three processes of crushing, grinding and beneficiation. In the process of crushing, the three-stage closed-circuit crushing is more suitable for the crushing of high-hardness manganese ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency; during the grinding process, the second-stage closed grinding is efficient. The grinding process can make the manganese ore mill more fully; in the beneficiation process, the more successful new processes that have emerged in recent years are representative: “stage grinding, weak magnetic separation – reverse flotation process”, “all Magnetic Separation Process", "Ultra-fine-wet magnetic separation tailing process"

1. The ore utilization rate of the magnetic separation production line can reach 90%, the water consumption in the process is small, the cost is saved, and the high profit space can be obtained;

3. The magnetically selected dust is collected by the dust removal device and will not cause air pollution. It is a creative process with high production efficiency, good product quality and no environmental pollution.

4. Low environmental requirements for the job site, high yield and low consumption even if the environment is not good.

Part II

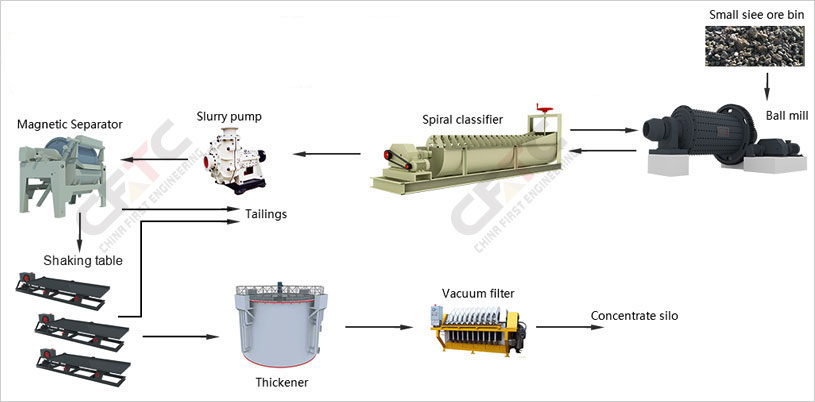

Manganese Ore Production Line

The mined ore is first crushed by a hammer crusher, crushed to a reasonable fineness, and then uniformly fed into a ball mill through a hoist and a feeding machine, and the ore is pulverized and ground by a ball mill. The ore fines ground by the ball mill enter the next process - classification. The spiral classifier cleans and classifies the ore mixture by the principle that the specific gravity of the solid particles is different and the rate of precipitation in the liquid is different. The washed and classified mineral mixture passes through the magnetic separator, and the magnetic material in the mixture is separated by magnetic force and mechanical force due to the difference in specific magnetic susceptibility of various minerals, thereby finally achieving a high quality product.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!